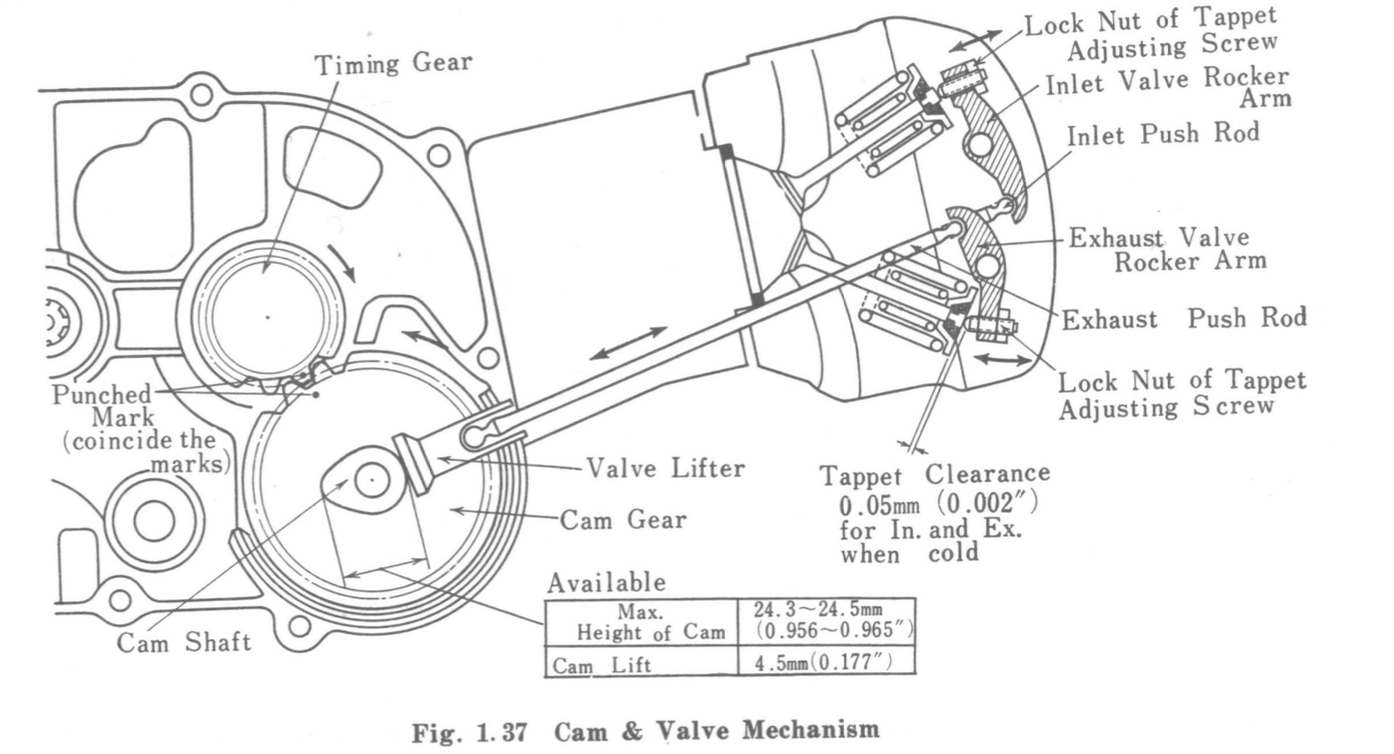

When Honda replaced the Super Cub push-rod engines with a new overhead cam model in the mid 1960s they needed to deal with the problems arising when using a chain to drive the camshaft from the crank.

the original 1958 Super Cub engine used push-rods to open and close the valves in the cylinder head, no cam chain required.

Cam chains tend to elongate as the bushings and pins wear with use and - without a mechanism to take the resulting slack out of the chain - mechanical problems can result. As explained in this article the chain can "whip" around in the engine causing noise and damaging valve train components; valve timing and can become erratic and, in the case of many of the older C90 cubs - which use camshaft mounted contact breaker points - ignition timing can be impacted too. To minimise these issues Honda introduced a cam chain tensioner.

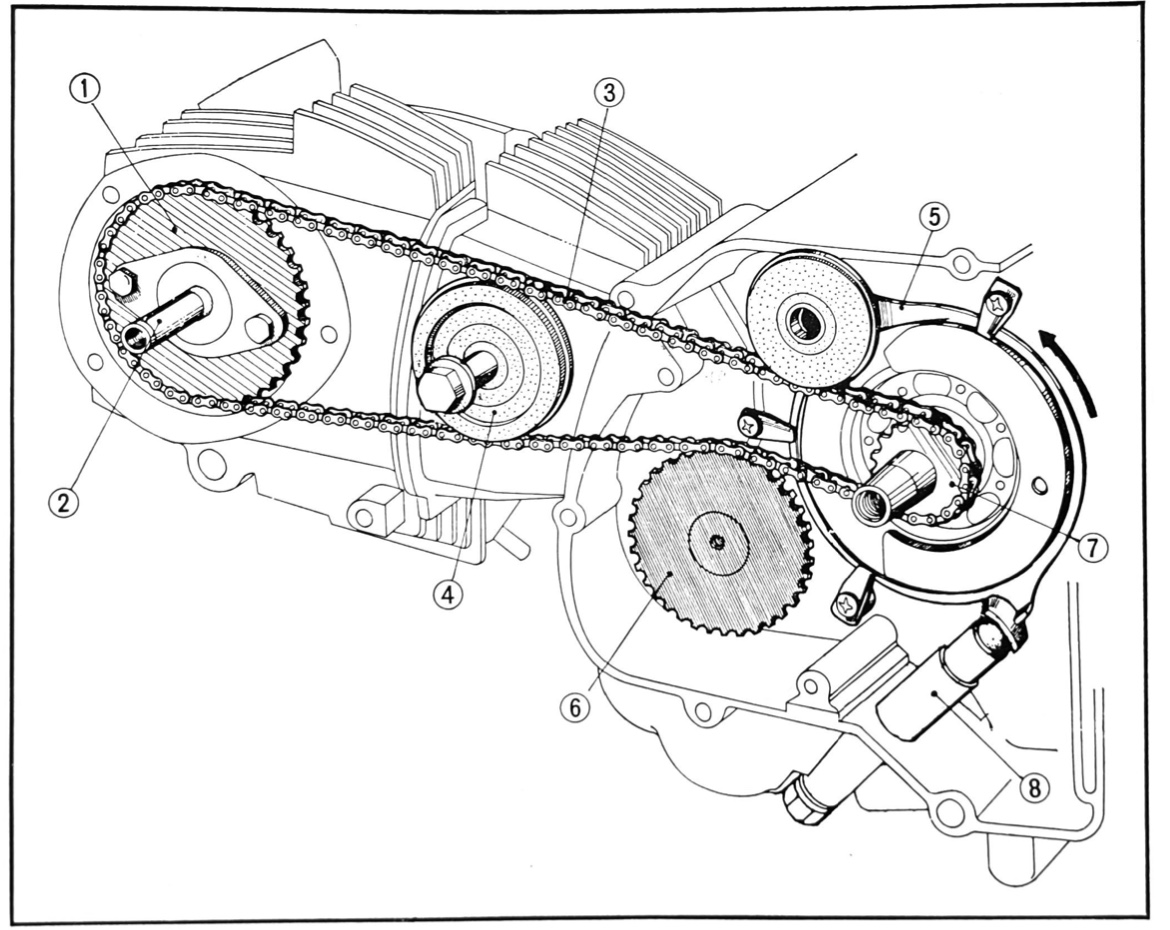

Operation

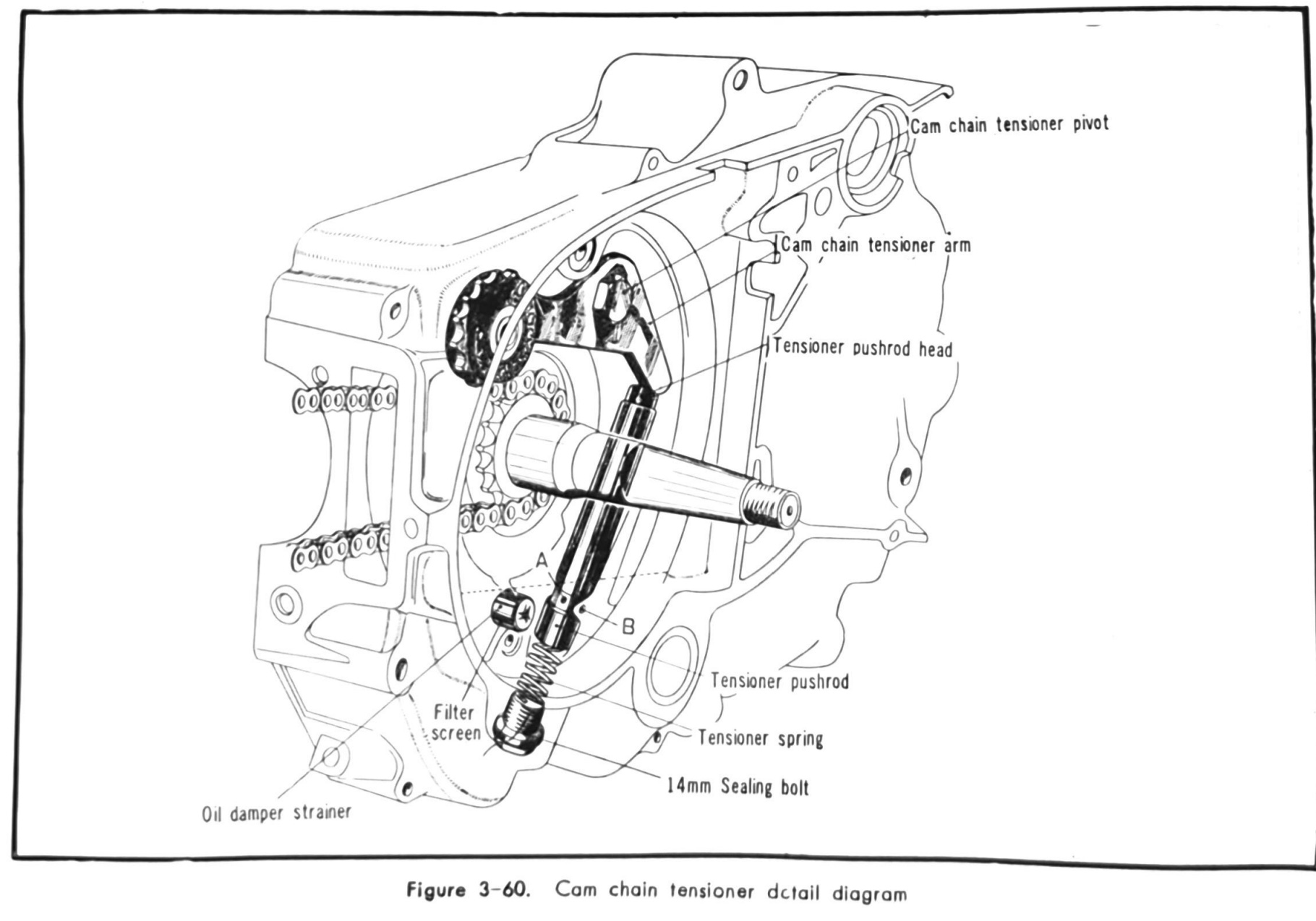

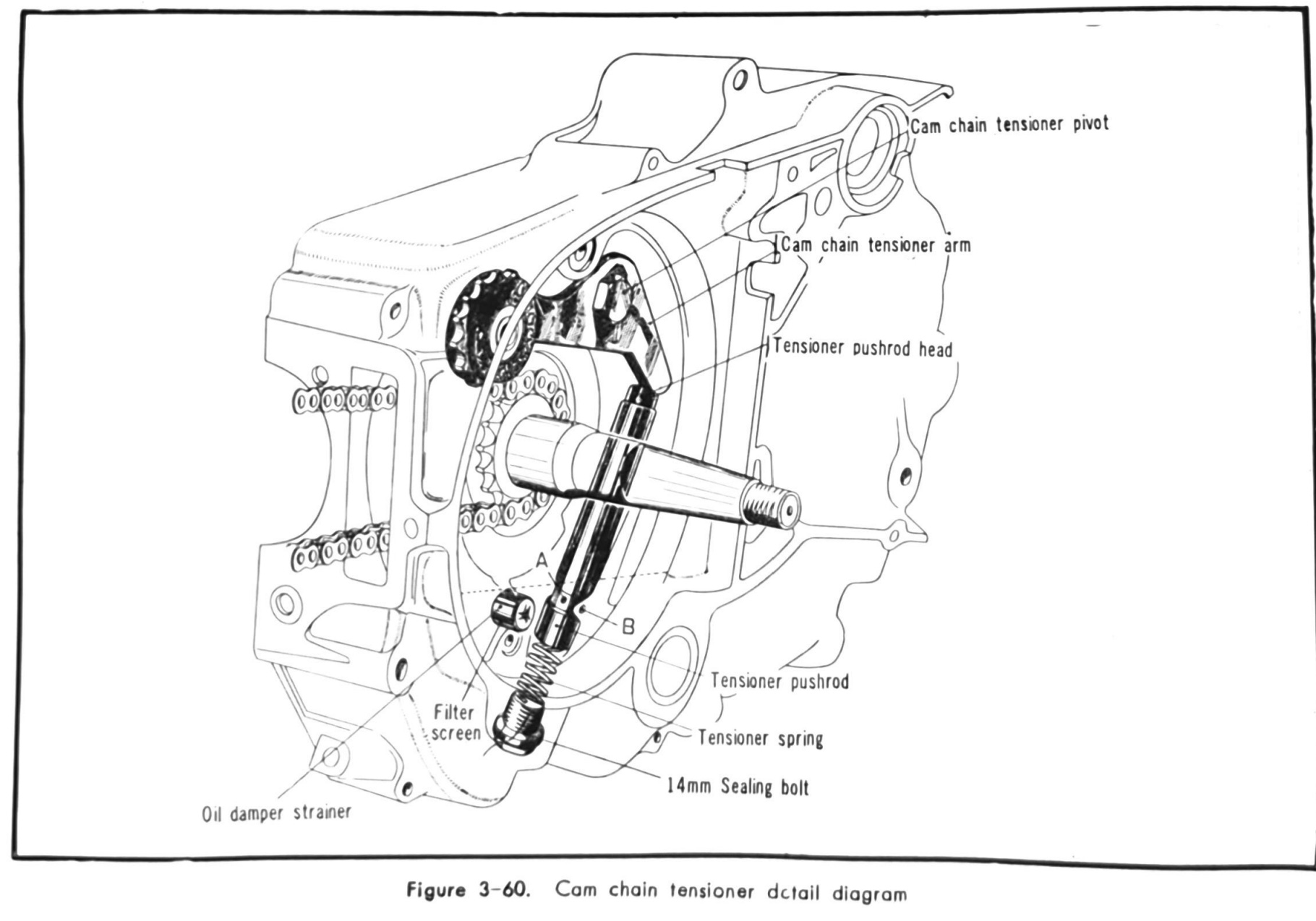

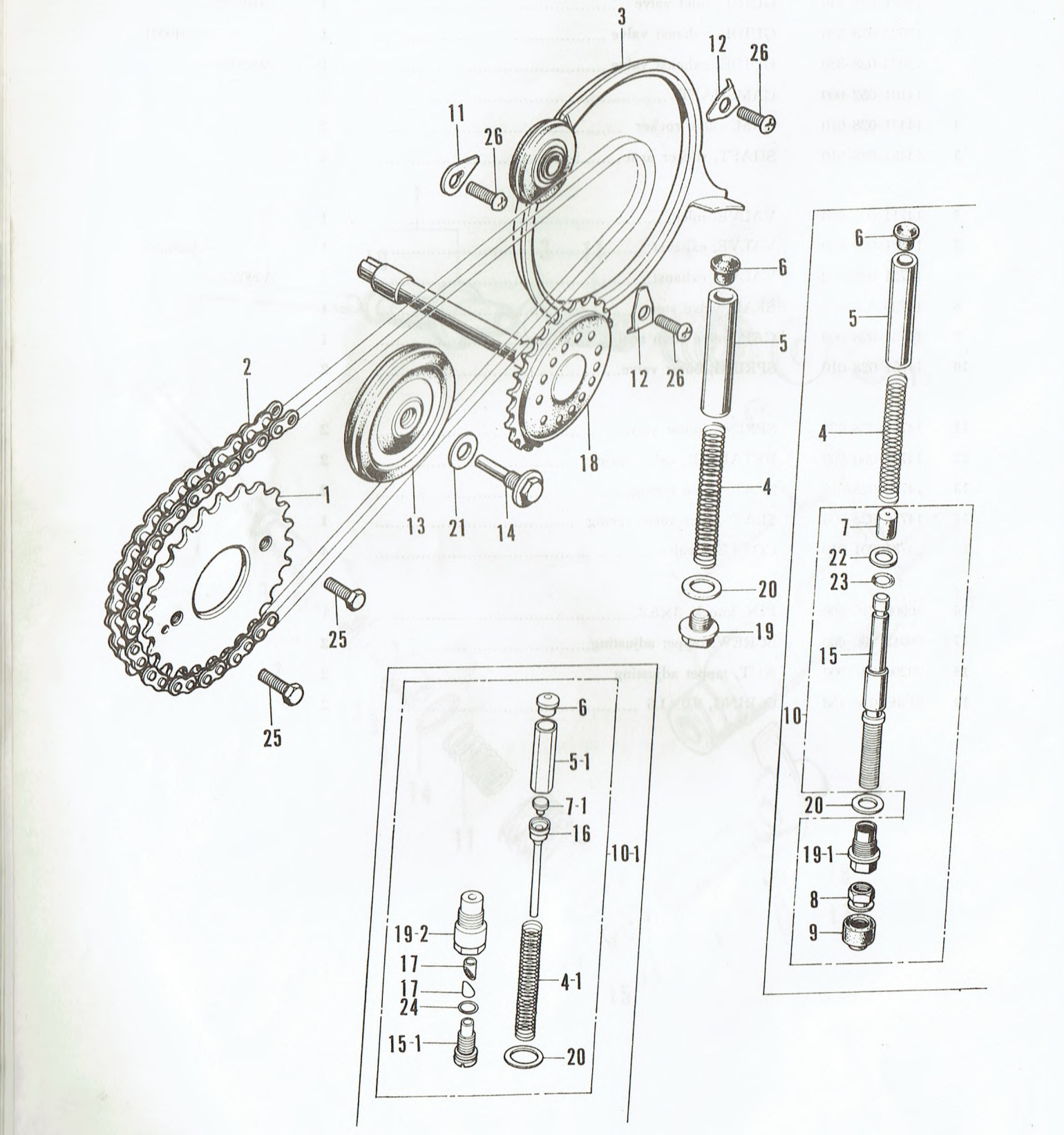

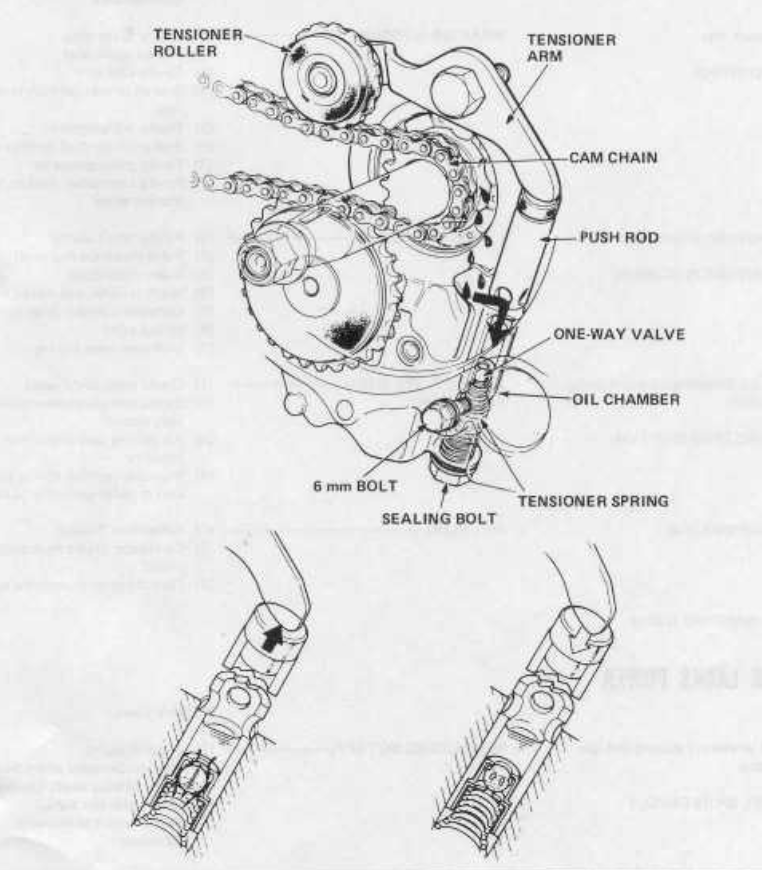

As shown in the diagram below the tensioner is made up of two parts, the tensioner push rod (8) and the chain tensioner (5). The rod pushes against a tab on the tensioner rotating it in the direction of the arrow so the roller mounted on the end of the tensioner takes the slack out of the chain.

Honda don't seem to have had much luck on this front and the cam chain tensioner department were kept busy for a couple of decades trying to get a satisfactory design.

1964 - automatic tensioner

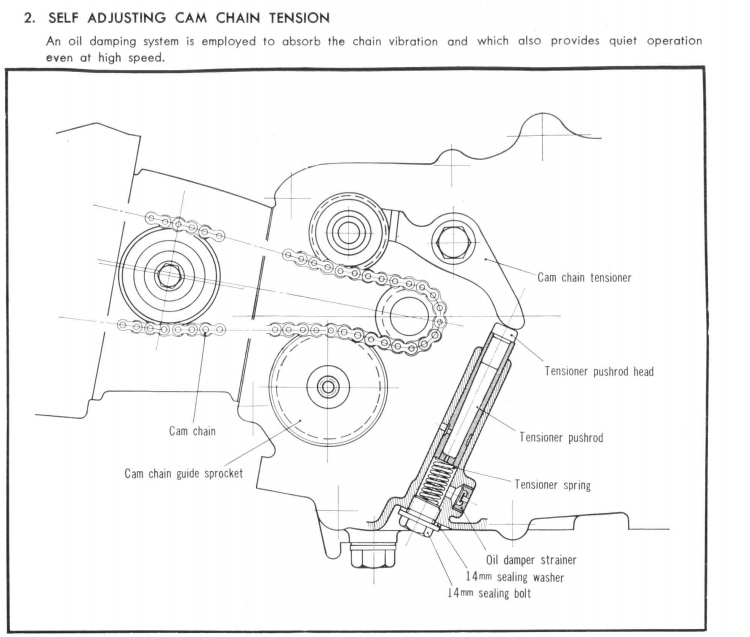

Honda started of with the best of intentions when they introduced their new overhead-cam engine in 1964, having installed a self adjusting system that would automatically apply the correct tension on to the cam chain without the need for periodic adjustments.

Honda C65 (the first overhead cam super cub)

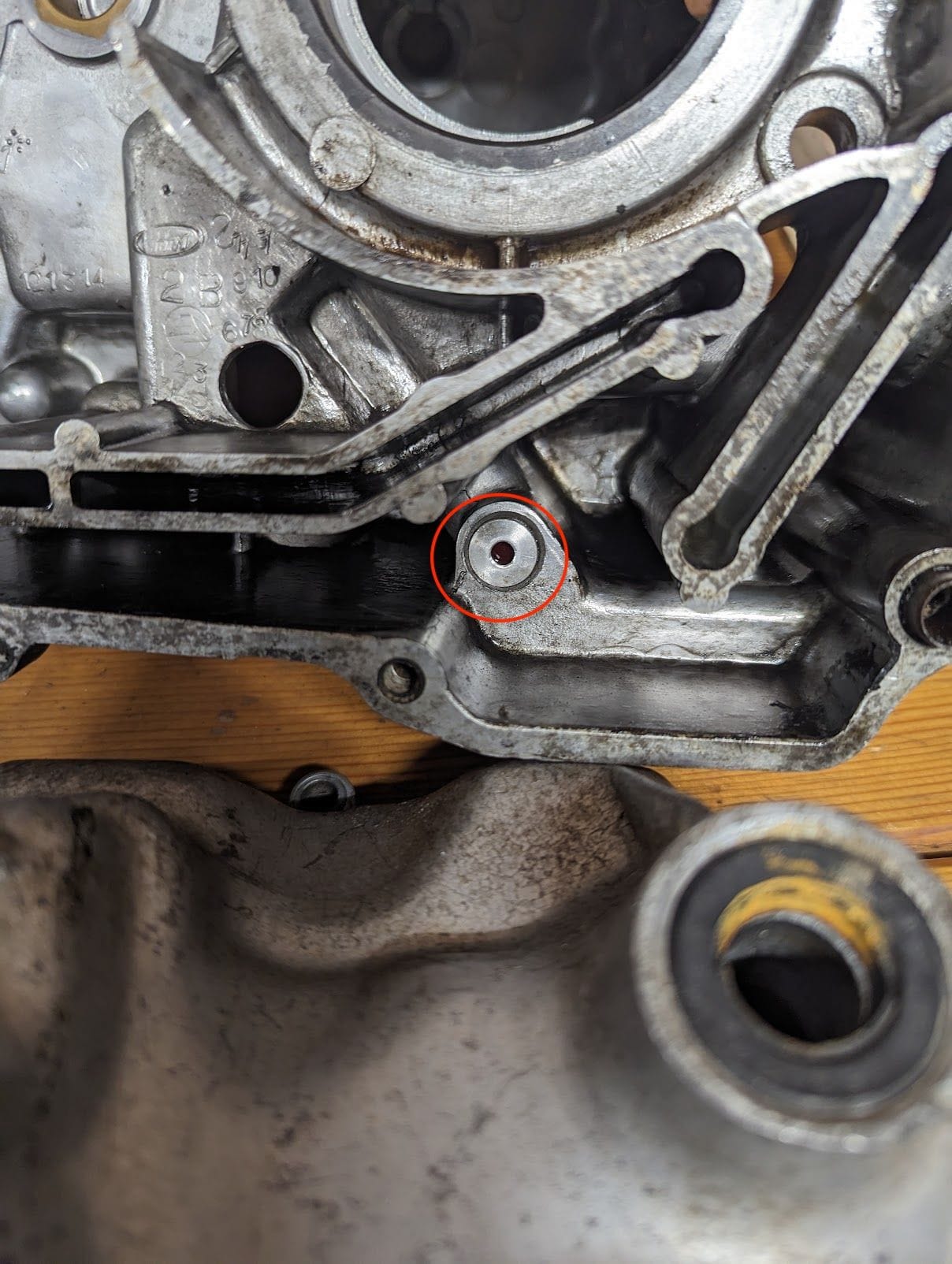

The solution is rather exotic: the chain tensioner spring compartment is flooded with oil which acts as a damper and this, in conjunction with the spring, helps keep the pushrod against the chain and reduces vibration. The oil enters through an oil strainer mounted in the left hand crankcase at the base of the compartment:

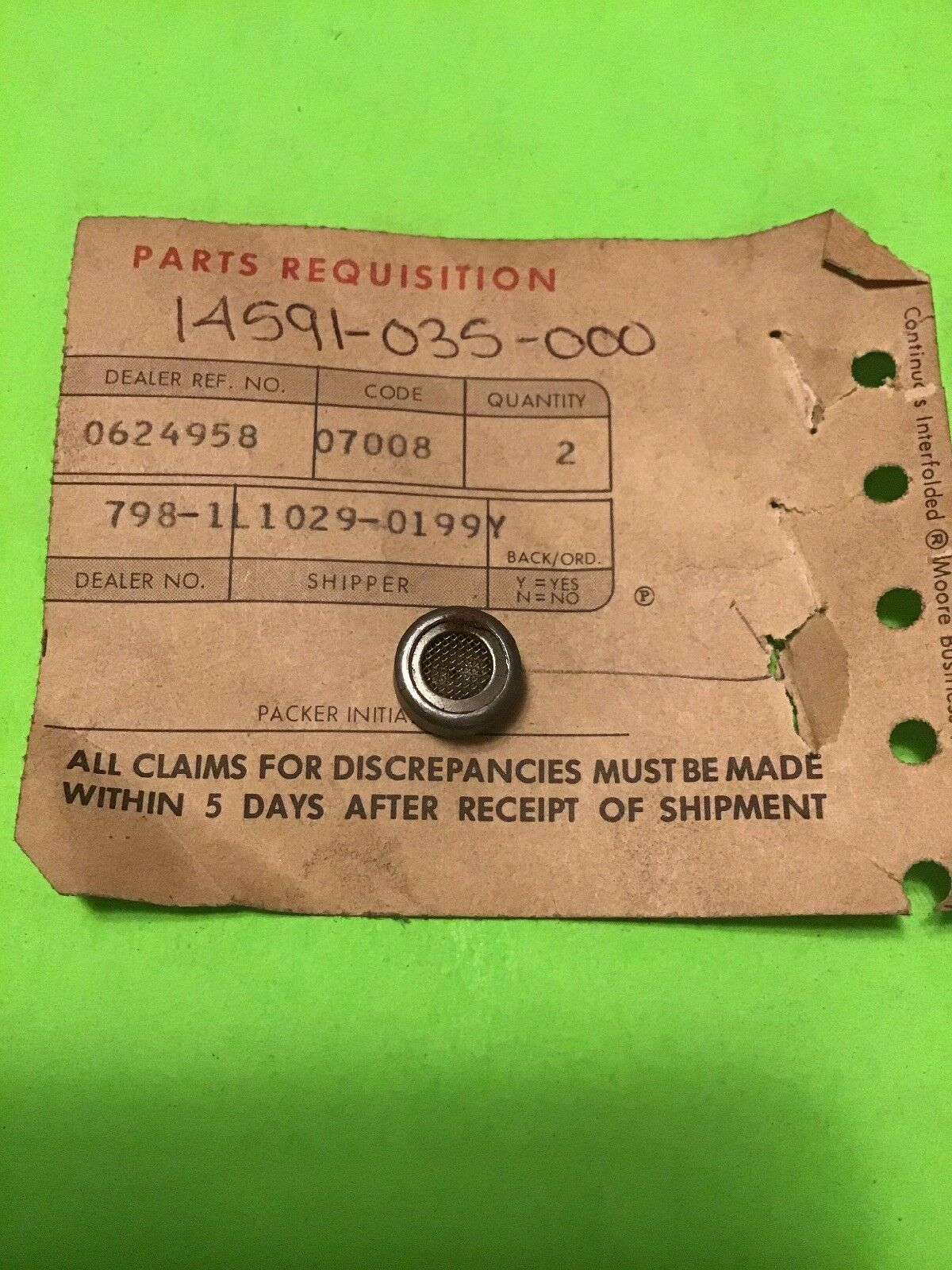

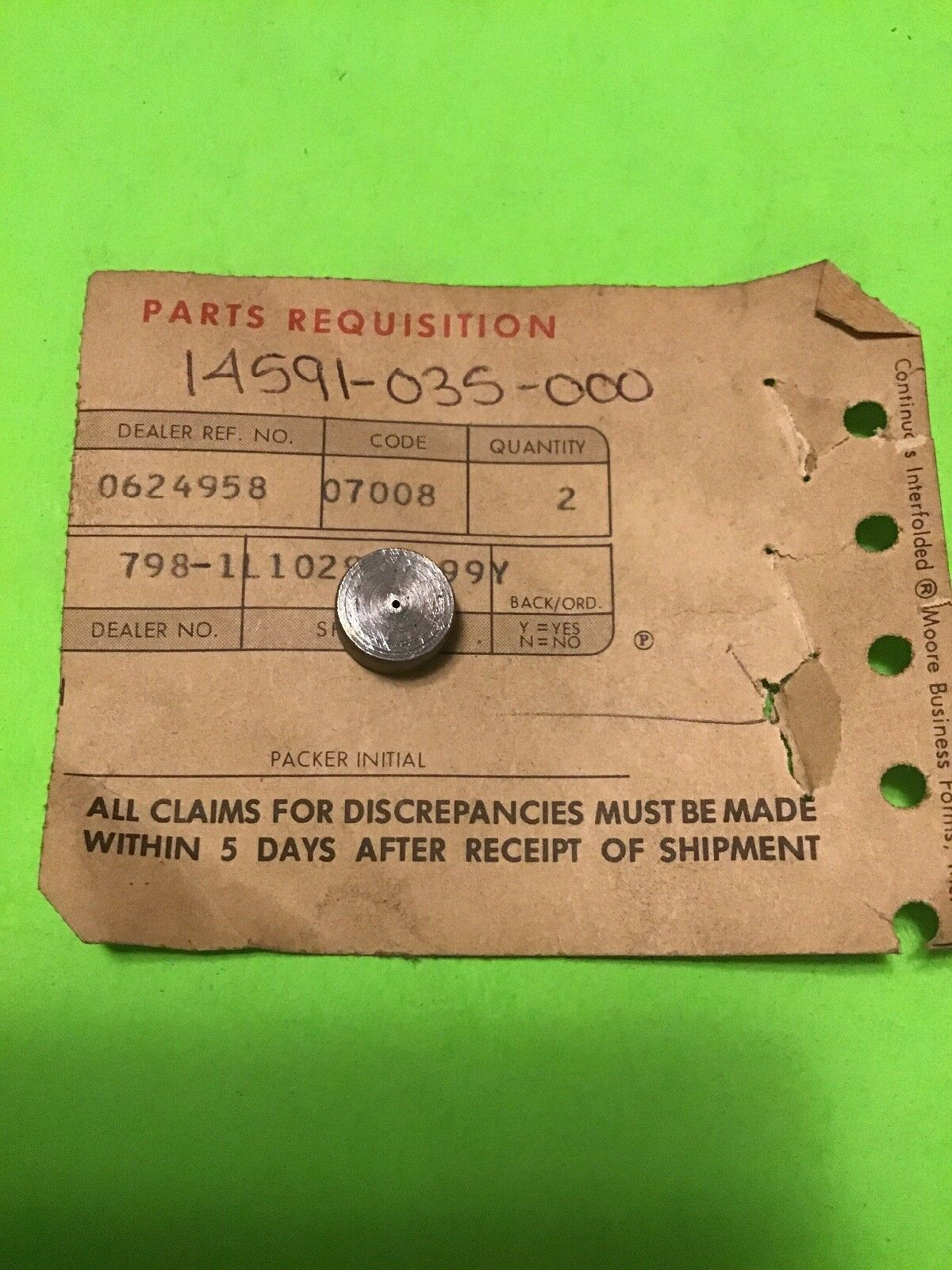

oil strainer

The shop manual says the oil strainer - which incorporates a mesh screen - acts in conjunction the centrifugal filter and the filter screen under the oil pump to purify the oil. It's hard to believe this tiny device made much of a difference to oil purification but I suppose it at least prevented any bits in the oil jamming up the tensioner. Presumably the strainer also plays a role in maintaining the oil level after oil fills the compartment, but it is not obvious how it works from the pictures.

EDIT it turns out the oil strainer does also function as a check valve that helps maintain the oil pressure inside the cam chain tensioner chamber. Inside the strainer there are two floating disks, a red phenolic disk and a metal disk with three small protrusions on the side facing the outlet hole that supplies oil to the tensioner chamber. When there is downward pressure on the tensioner rod the oil pressure pushes the the disks against the inside of the strainer, sealing off the inlet on the engine side. When the rod moves upwards the disc is pulled away from the back of the strainer allowing oil to enter. The three protrusions on the metal disk prevent the disk from sealing off the orifice on the chamber side.

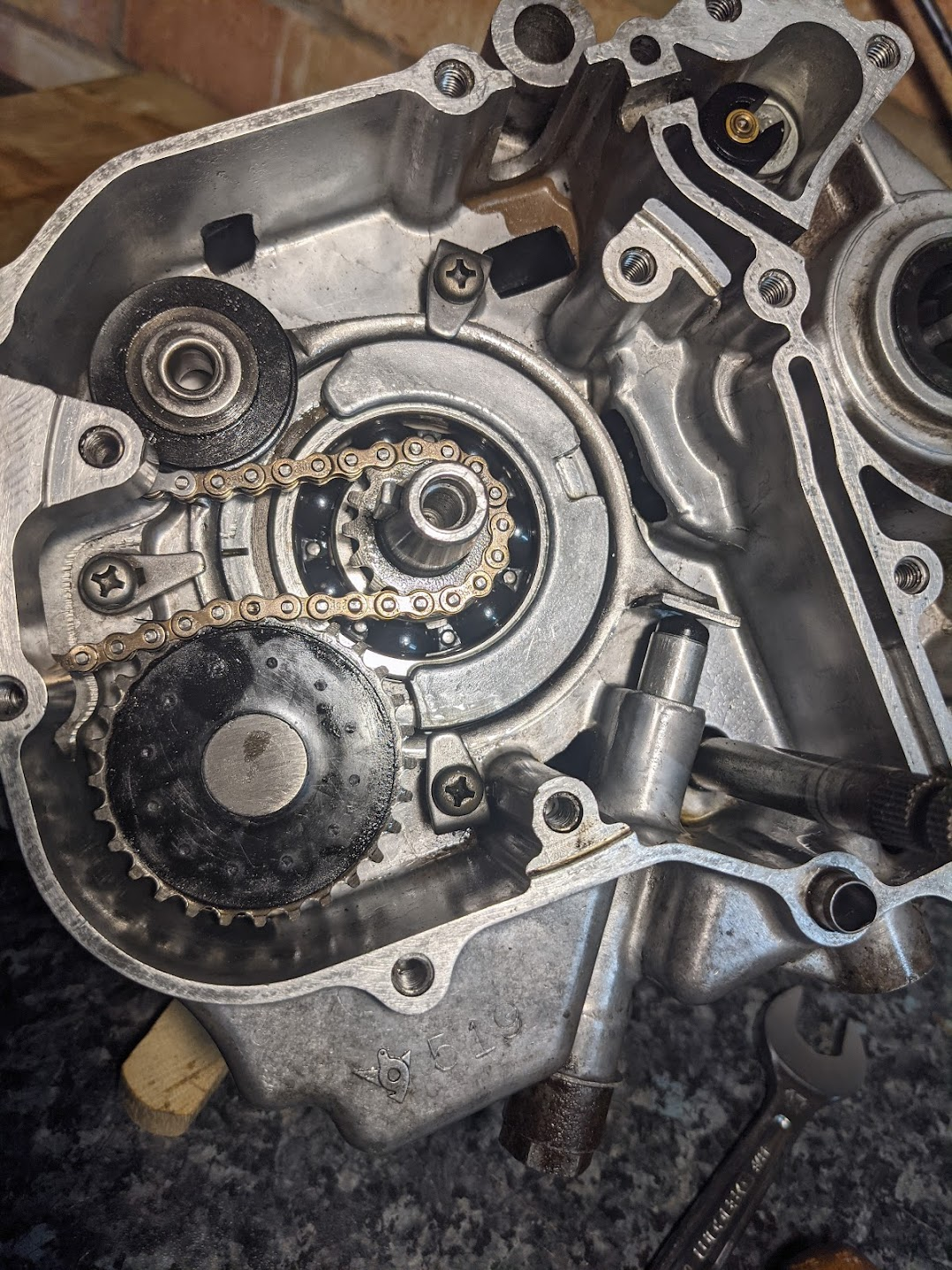

This same system was used in the CM91 (the first cub to use the new 89cc OHC engine) and the early C90s and CT90s:

CM91 left hand crankcase from around 1966 (left) and a CT90 case from around 1967

After the engine starts, the reciprocating motion of the pushrod forces the air above the oil level in the tensioner spring compartment out of the hole in the pushrod (see "A" in the diagram below) and into the crankcase through a hole (B).

Eventually the level of the oil rises sufficiently to submerge hole B so that the the tension spring compartment is constantly flooded with oil. The design was quickly modified so presumably did not work as well as expected.

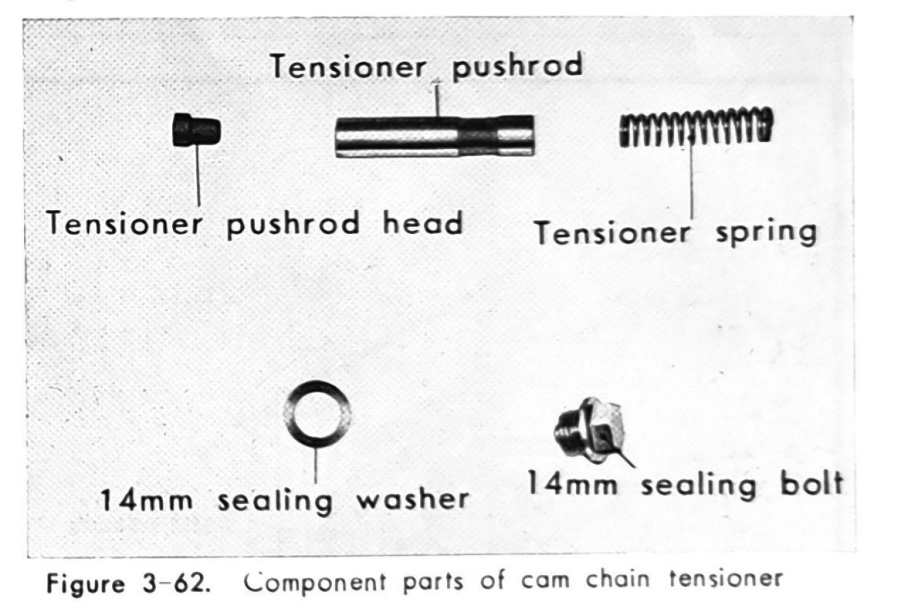

image from the CM91 shop manual (left), and pictures of the parts (middle and right)

1968 automatic tensioner v2

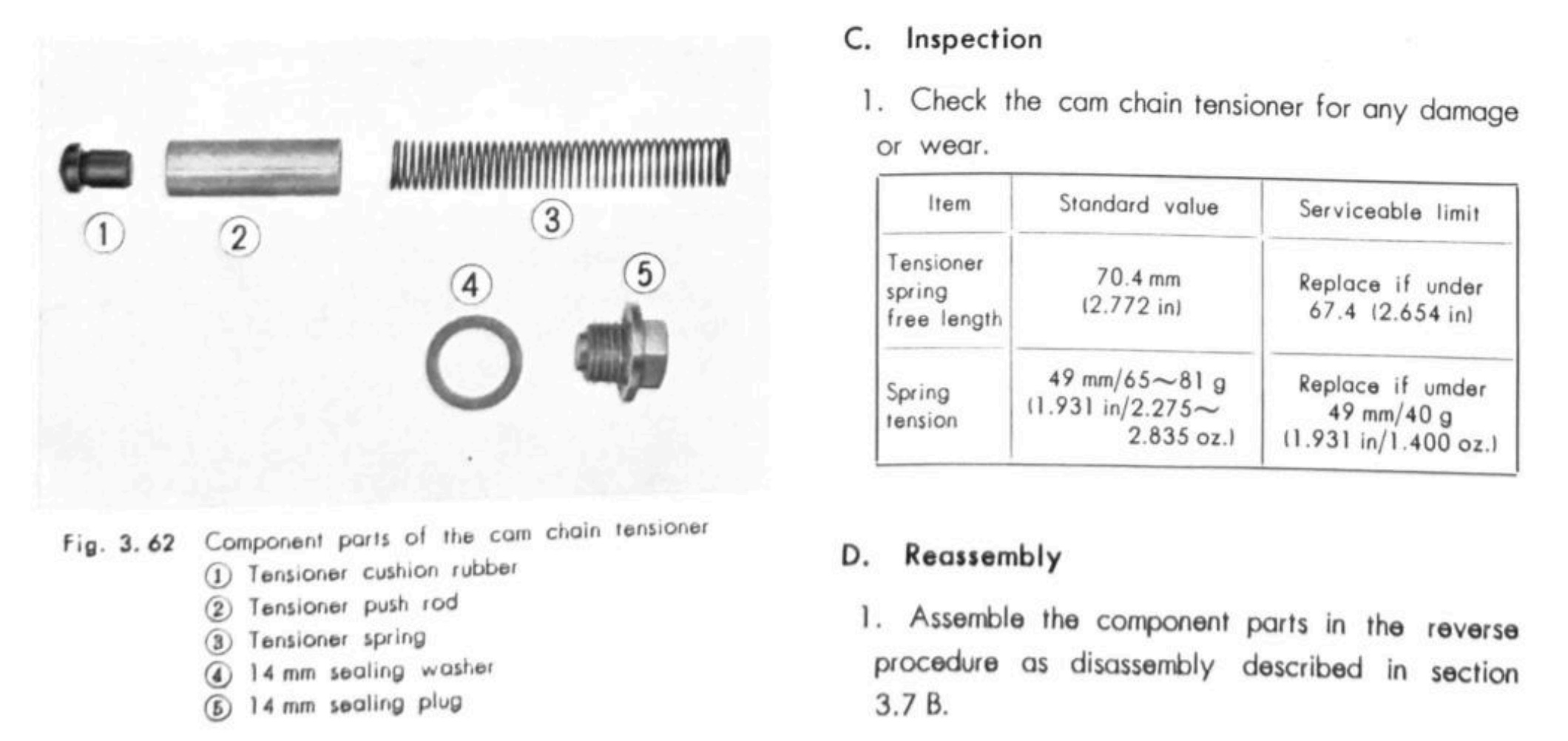

Honda's second attempt still aimed to use a combination of oil pressure and spring power to maintain tension automatically, but the vented rod was replaced by a shorter unvented version and a substantially larger spring, perhaps indicating the original version was not able to exert sufficient tension to prevent chain noise.

Entry describing the parts from the 1971 C90 shop manual

Early 1970s - mechanical tensioner

These modifications appear not to have worked either and at some point in the early 1970s Honda replaced the sealing plug with this contraption:

The spring applies the correct tension and then the rubber tipped rod shown above is screwed up through the spring to the base of the pushrod preventing it from moving downwards. Presumably this solved the noisy chain problems, but the mechanism could no longer be properly be said to be automatic.

1977 mechanical tensioner v2

At some point in the 1970s Honda got rid of this idea too and came up with a more elegant design (this is the version used on the C90z2 and C90zz cubs made between 1977 and 1982).

The two small collars (shown 2nd from the right in the picture below) slide past each other and lock the guide rod (second left) in position when pushed by the adjusting screw that fits in the sealing plug, and this holds the pushrod tight against the tensioner. Simply loosen the adjusting screw so it releases the guide rod and the spring will apply the correct tension, tighten the screw and the plunger is gripped in the correct place. A lovely simple solution!

Three of the four different versions used on the UK c90s are shown in the 1976 parts list:

"deluxe" model manual tensioner

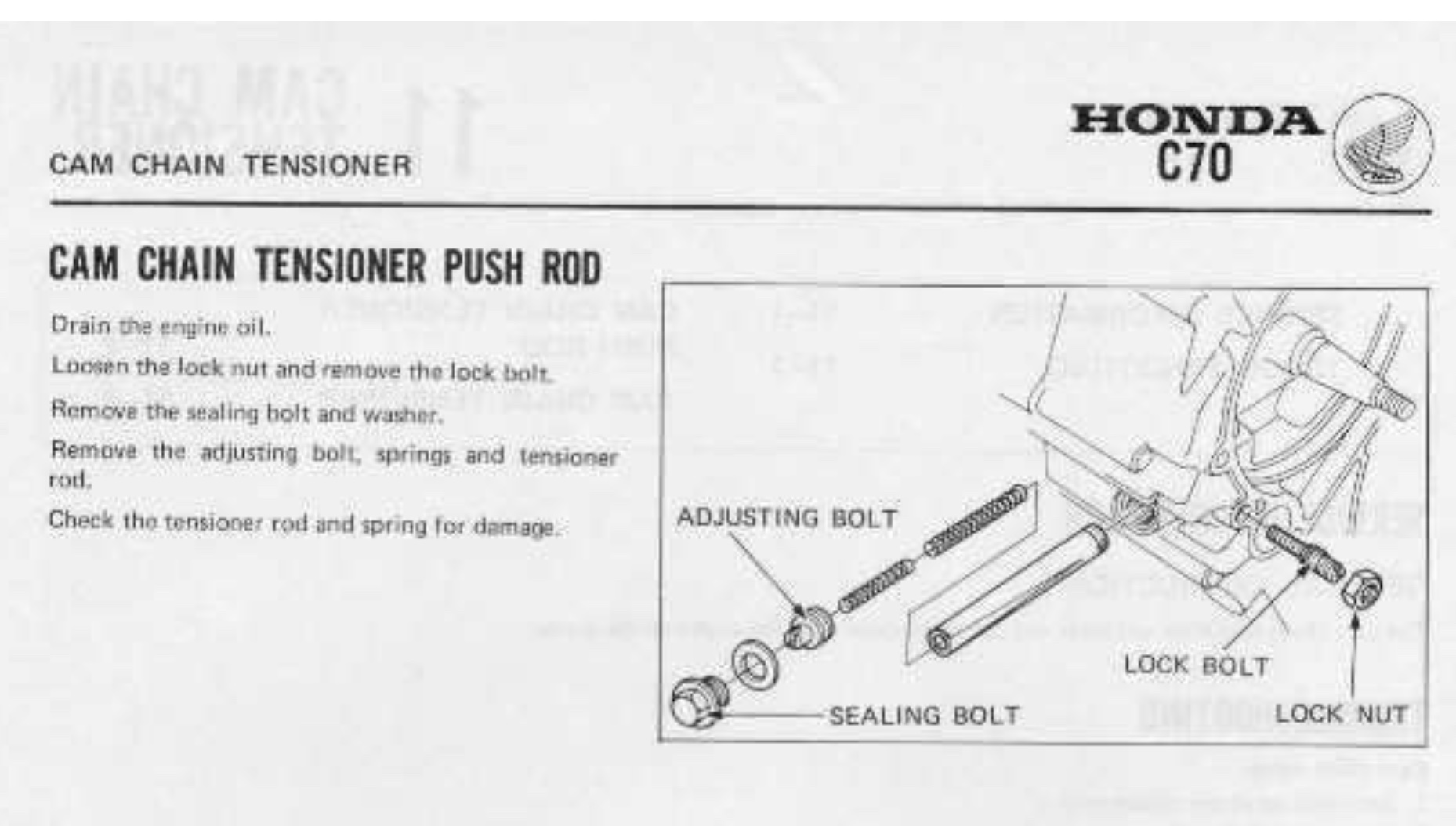

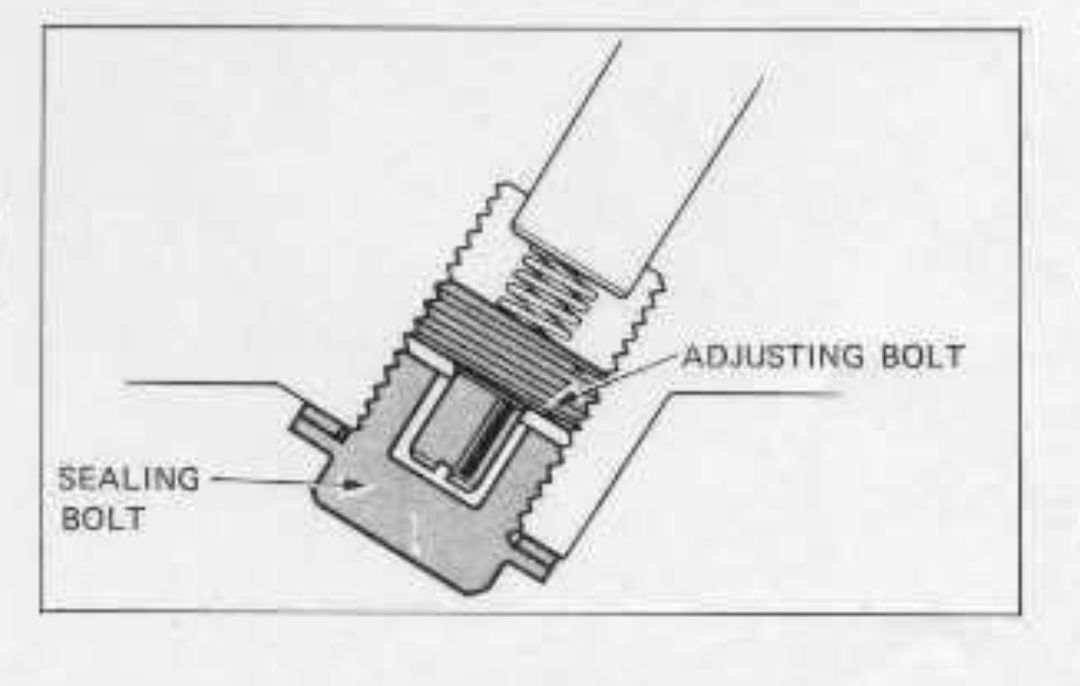

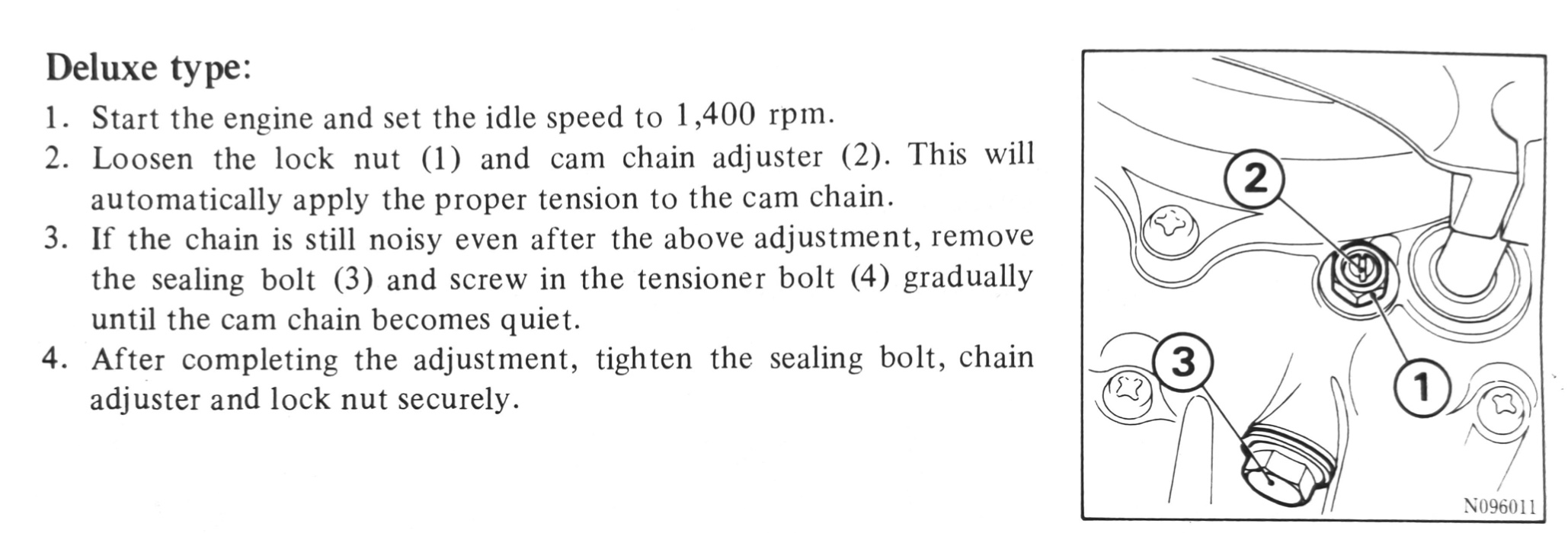

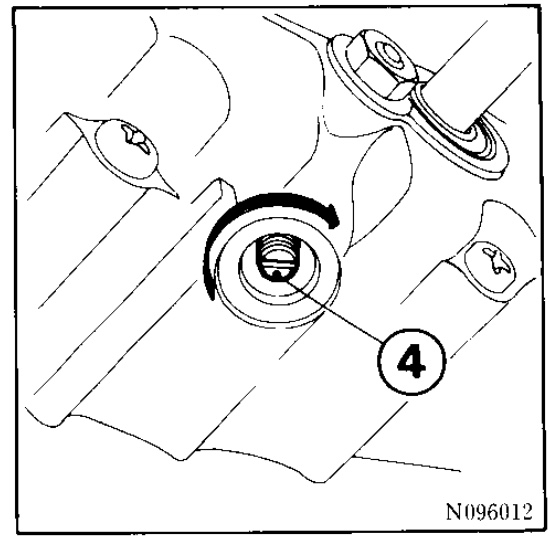

Honda treated those countries that got the "deluxe" C90K series (e.g Australia) with yet another version. This one - based on a design original introduced with the C70 in the early 1970s - is arguably the most byzantine of the lot.

The pushrod is still spring loaded but locked in place by a screw accessed from the side of the crankcase. The mechanism also allowed for secondary adjustment that could be used to increase the preload spring tension.

Removing the sealing bolt and turning the adjusting bolt increases the spring tension. This version was also used on certain CT90 models (right)

1984 automatic tensioner revisited

in the early 1980s the Honda cam chain tensioner department had another brainwave and reverted back to their automatic adjustment/oil damped approach, but with a twist. This is the version used in the 12v cubs.

Apparently this design hit the spot as it has not been altered since it was introduced.

automatic tensioner (1980s)

The tensioner pushrod position is maintained by the presence of oil in the chamber beneath it. Oil splashed from the cam chain enters the ports in the side of the pushrod and fills the void on the underside of the rod.

When the tensioner spring pushes the rod up to remove the chain slack the one-way ball valve opens and allows oil collected in the push rod to flow into the chamber below. When excess tension starts to move the rod downwards, pressure from the oil in the chamber forces the valve closed so that the position of the rod is maintained.

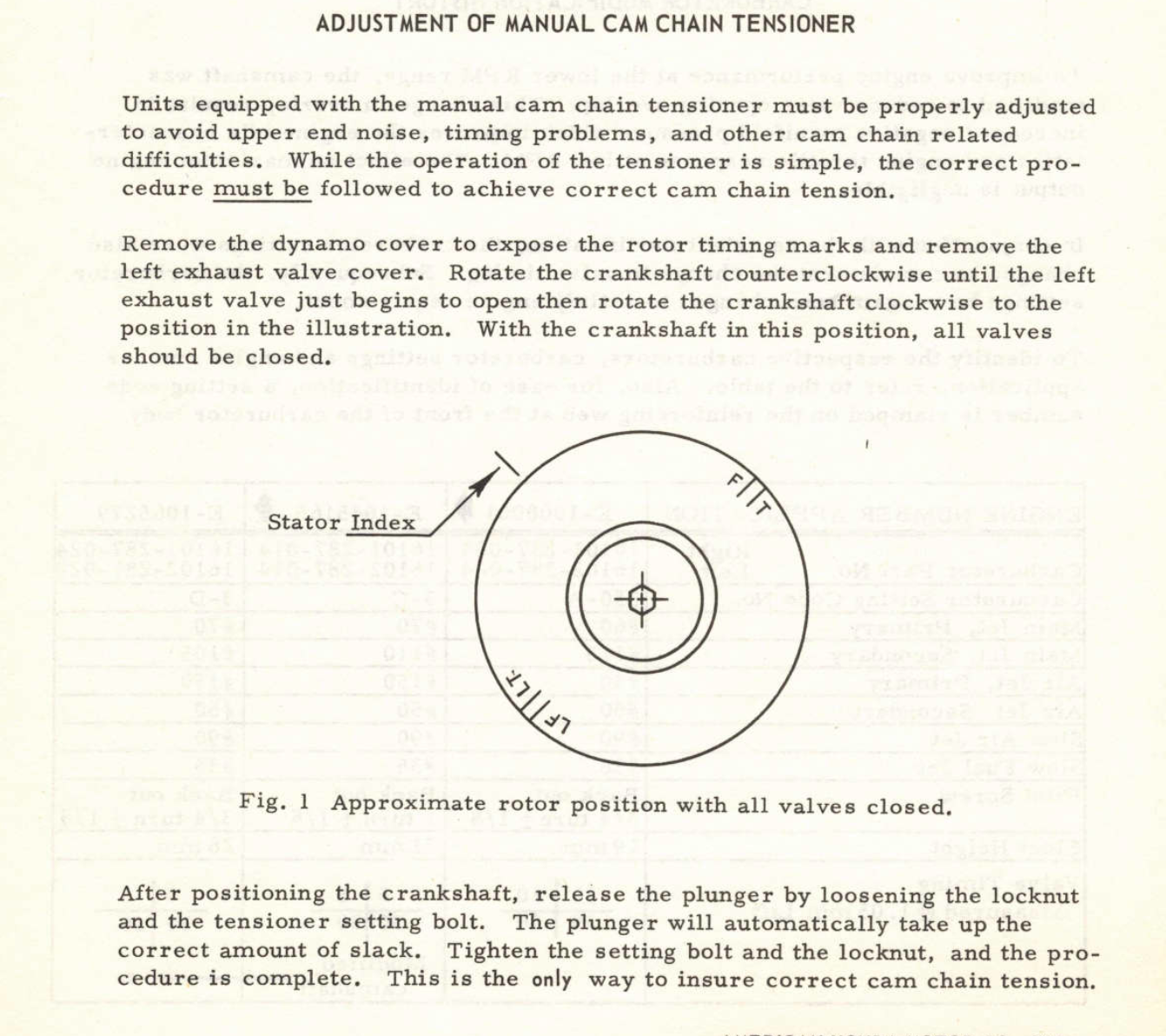

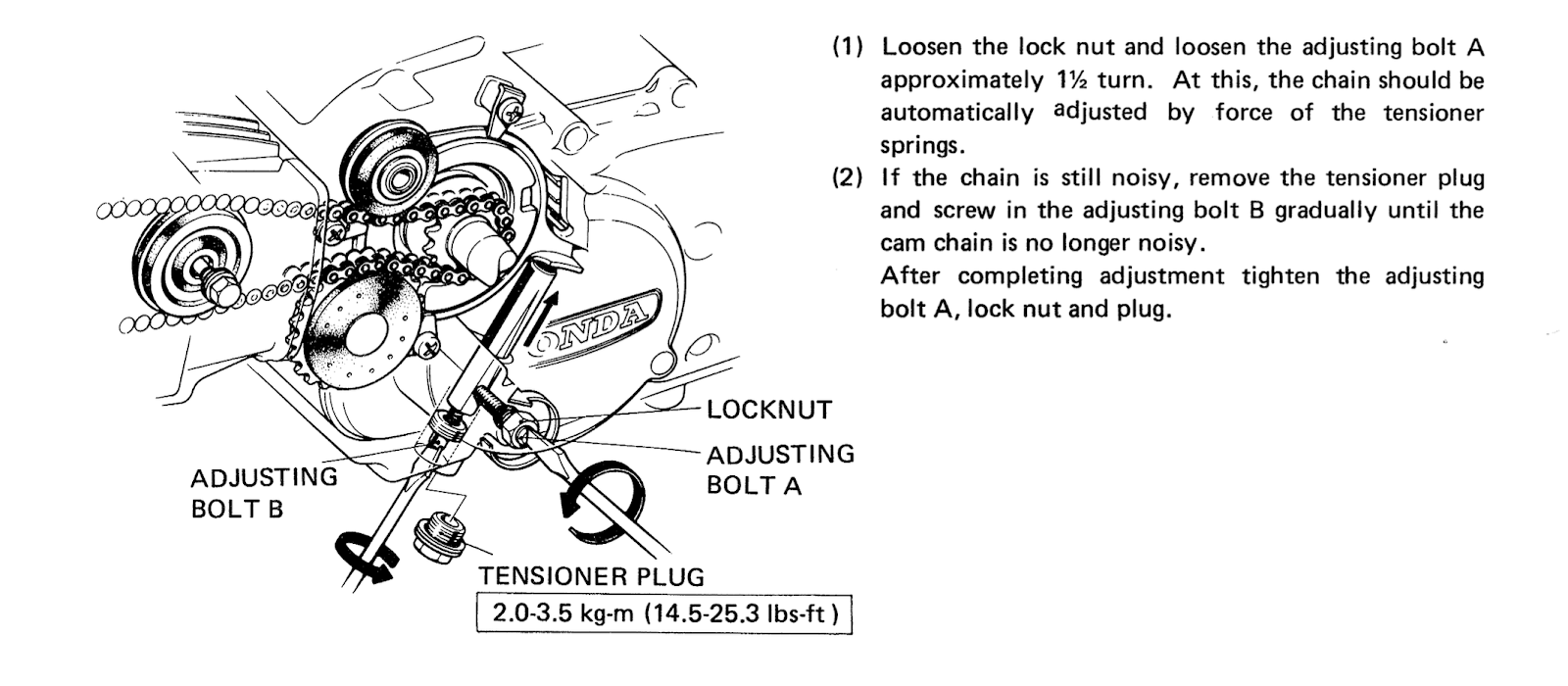

Adjustment

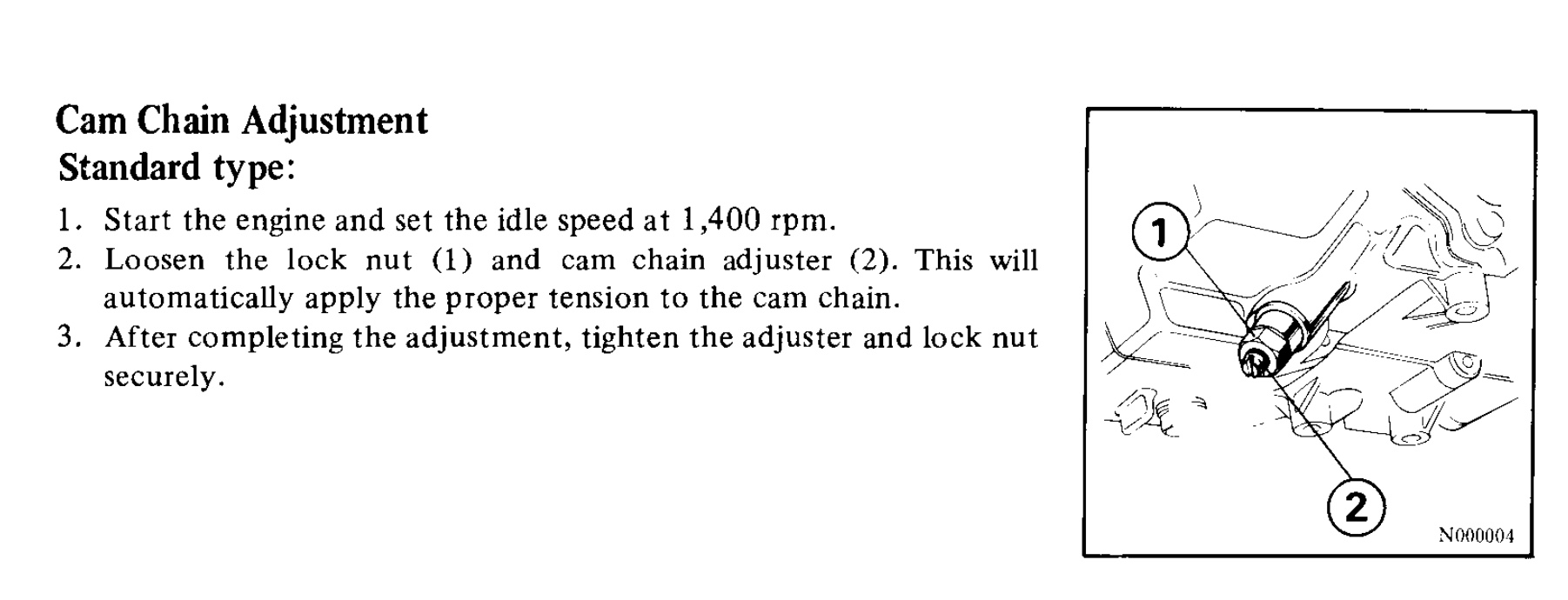

The CT90 shop manual and late 70s C90s owners manuals say that the mechanical tensioners should be adjusted while the engine idling, which I suppose is logical since when the engine is running the tension will be on the underside of the chain and the slack is on the trailing side that the tensioner pushes against.

adjustment on the standard manual tensioner fitted to the C90Zs (left)/ "deluxe" adjustment (centre + right)

Although the method mentioned in the user manual is convenient, the most reliable method is to adjust the tension while the engine is at TDC on the compression stroke (you have to do this when setting the valve clearance, so this is a good opportunity to do the cam chain tension too). This works because you are turning the engine to a point where the camshaft is not trying to rotate the engine, allowing the adjuster spring to take up all the slack.